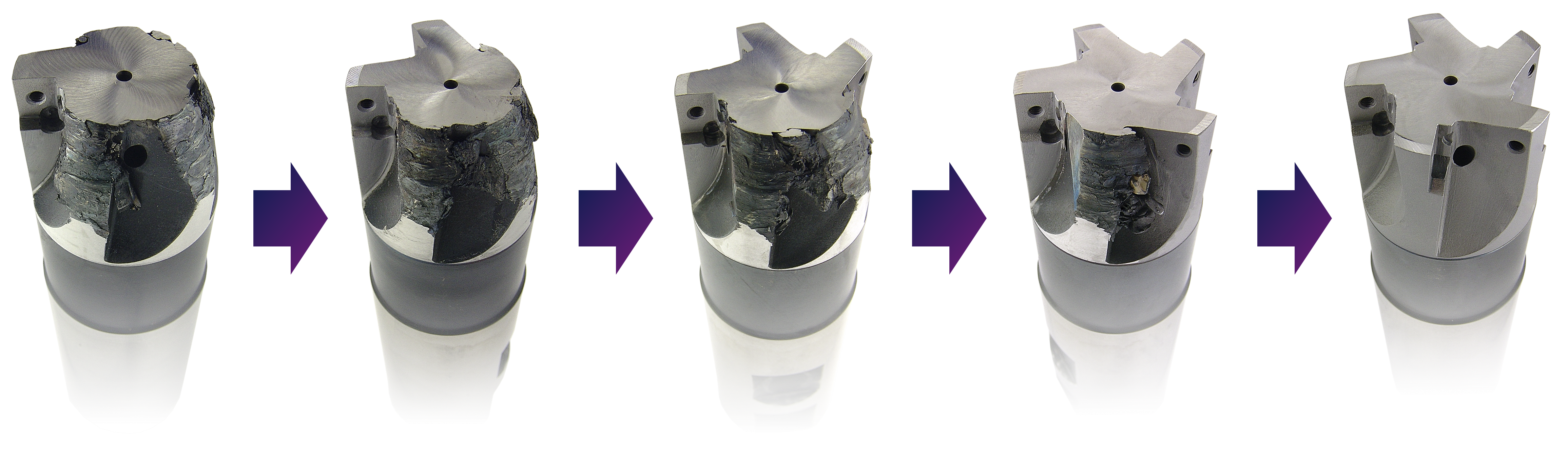

This is not a total loss!

Did you know that you can save up to 78% on average by repairing?

In our NUBIUS production we give new dynamic to used tools. If a screw-in milling cutter is still missing in your production range, take a look at our online store! If you don’t find what you are looking for there either, we have a particularly service for you: we can also support you with individual custom-made products on request.

NUBIUS establishes its own standards in repair technology and reconditioning, even for the most severely damaged tools and precision parts. We solve manufacturing problems when damage occurs due to collision, tool breakage or in cases of worn insert tools, precision parts and special machine parts.

REPAIR AND OVERHAUL

When tools malfunction due to breakage, collision, NUIBUIS is there to help! After all, downtimes are the costly!

We repair and grind precision tools, special tools or XXL-tools, but also measuring equipment.

Learn more about our services by clicking on the list below:

NUBIUS identifies new possibilities for savings in a wide range of metalworking industries.

Repairs of severe damage are often considered impossible – NUBIUS can show that many things are possible after all.

Savings effects are available in all companies. You just have to be willing to recognize and use them to achieve the benefits.

There is savings potential in every company!

The potential for savings is possible with consequent repairs and permanent maintenance.

In the event of a breakdown, prompt intervention is possible because in these situations a repair can be performed as soon as possible.

This is particularly for special and stepped tools, which have long delivery times when manufactured but in the case of damage can be repaired and send it to you with a our urgent delivery service in 1-3 days.

Reparation of cutting tools with metal carbide inserts

Our customers come from all areas of the metalworking industry: automotive industry and its suppliers, engine manufacturing companies, mechanical engineering, plant engineering, precision engineering, compressor manufacturers, metal construction, tool manufacturing, mold making industry, foundries, marine industry, automation technology, gear manufacturing, turning workshops, drive technology, machine tool sales companies, grinding shops, mold and die making, fittings construction, paper machine industry, medical technology, hydraulic aggregate construction, gearbox construction and many others …

NUBIUS can repair and rectify the following types of damages:

- pocket insert damaged

- damaged threads

- broken screws in the thread

- broken elements on the tool, such as pins

- cracks in the tool body

- collision damage to the tool

- tool is bent, twisted, deformed

- damaged positioning holes

- worn and damaged mounting holes

- axial and radial deviation of the tool

- various types of tool holder damage

Repair of measuring devices

NUBIUS also provides repairs of defective mechanical parts of measuring devices.

We repair a wide range of damages. As a result, the measuring devices become functional again and can be used in production again.

We repair measuring devices with the following damages:

- between the measuring device body and the round indicator disc

- the mechanism is blocked, the needle can no longer move or the needle gets stuck during measurement and the readings are not always correct

- the indicator needle no longer moves or has fallen out

- the protective disk is heavily scratched, cracked or has fallen out or no longer holds in the soket

- the measuring device has fallen, the needle does not move any more

- the dial is damaged and can no longer be turned

- the dial above the locking bolt is overtightened

- the pressure force of the measuring cylinder is no longer sufficient

- the measuring device shows wrong values repeatedly

- the movable measuring cylinder is stiff and gets stuck frequently

- the push buttons get stuck and can no longer return to their original position

- Measuring devices with defective mechanics are completely reconditioned and made functional again

Grinding precision tools

The NUBIUS grinding service turns blunt tool edges into sharp-edged tools again!

Worn tools produce scratches, poor ,rough workpiece surface quality. Our sharpening service will help you.

Tools that have become blunt and unusable are re-sharpened and re-coated. You will be left with fully functional tools.

Grinding precision tools offers several advantages:

- Improving tool performance: Grinding brings precision tools to their optimum cutting edge geometry and condition. This allows them to cut more efficiently, produce cleaner cuts and achieve a higher surface finish. The ground tools also provide better dimensional accuracy and precision.

- Extending tool life: The grinding process removes worn, damaged and signs of a deteriorated tool. This significantly extends their service life, resulting in lower tool costs and less tool changes. Grinding tools maintain their cutting performance over a longer period of time, allowing them to be used for an extended period of time.

- Adaptation to specific requirements: Grinding allows precision tools to be adapted to specific applications and materials. Depending on the requirements of the machining process, the cutting angle, cutting geometry, cutting angle and other parameters can be optimized. This results in improved performance and efficiency in specific operations.

- Cost savings: Grinded precision tools can be an economical solution because they have a longer service endurance and need to be replaced less frequently. This leads to reduced tooling costs and less downtime in production. Optimized tool performance can also reduce machining times and increase productivity.

- Increased quality: Grinded precision tools typically deliver higher quality machined parts. They produce more precise dimensions, better surface finishes and reduce the risk of defects or waste. This helps improve the overall quality of the manufactured products.

KATALOG

In unserem Reparaturkatalog stellen wir Ihnen unsere verschiedenen Leistungen rund um das Thema Werkzeugreparatur, die Herstellung von Sonderwerkzeugen sowie unseren Schleifdienst, vor.

Sie wollen mehr erfahren? Dann 👉 klicken Sie hier 👈 und werfen Sie einen Blick auf unsere anderen Kataloge und Broschüren.

Kostenlose Abholung Ihrer Werkzeuge!

Wir bieten Ihnen eine kostenlose Abholung Ihrer kaputten Werkzeuge an! Mit uns sparen Sie nicht nur bei der Reparatur, sondern auch beim Versand.